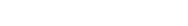

Robotics is no longer just a buzzword; it’s vital to industrial manufacturing. Robotic solutions are completely redefining the way manufacturers get work done on the floor & how they prepare their products for market.

An optimised production line is one of the chief benefits of robotics. Robots typically yield higher output in less time, to excellent standards of quality and consistency. Many forward-thinking small-to-medium processors are investing now, and are already reaping the rewards of higher efficiency, higher revenues, lower cost, and better customer service.

In this blog, we share more about how robotics and automation are transforming production lines for manufacturers across Australasia and beyond.

1. Improved quality and reliability

Robotics bring unsurpassed quality and speed to manufacturing and end-of-line product handling. This yields consistent, uniform output that satisfies customers and builds brand value.

Robotic equipment is much more precise than humans can ever be. Robots will work to these exacting levels of precision repeatedly, without

Whether it comes to material handling, assembly, welding, palletizing, or other key functions, robotic systems ensure the job is done to exact specifications, every single time.

Artificial intelligence and machine learning advancements are making robots even more accurate and autonomous than past generations of technology. A level of process improvement & correction can be made without operator intervention.

The result is a

2. Minimised risks

Robotics are indispensable when it comes to lowering risks for a human

Factory downtime is reduced when robots take over hazardous or repetitive work, translating to fewer employee absences due to injury or fatigue. And a strong safety culture (in which robotics can play a key role) results in more engaged, productive employees.

The improved safety lowers risk for manufacturers in yet another way: fewer financial burdens due to worker injuries. Safer, more automated floor operations lower the chances of having to pay outsized healthcare and insurance costs.

3. Continuous production

For a lot of brands it is an advantage to be able to continue production after hours. Most manufacturers will agree that shift work comes at a cost and is challenging to recruit for. While human workers have natural limits, robots can make up the difference.

Robots can be programmed to work 24/7 with minimal supervision. As technology improves and systems become increasingly accurate & fail-safe, this means more processing work can take place outside of traditional work hours.

The fact that robots never tire, combined with their ability to get work done at all times to a higher standard, means manufacturers can move more higher quality product faster, gaining a critical competitive advantage.

4. Boosted worker productivity

While concerns have arisen about automation and AI taking jobs away from humans, there is much more to the story. Rather than being a universal threat to workers, robots in many cases actually make the human workforce much more productive.

The demand for human ingenuity is going nowhere. People are needed for programming, technical support and other higher-level roles that entail working with developing technologies.

By introducing robotics, employers will be able to attract top talent for more value-adding roles. At the same time, companies can unburden lower-level workers who were less able to contribute to company growth, and instead upskill them to more satisfying, less injury-prone roles. This all adds up to happier staff and higher production rates.

Robotics enhances production lines in many ways, but bringing in robots takes some careful planning. The advantages of a superior process and product, lower risk, and higher worker productivity are well worth the investment. That said, a robotic solution should fit the particular needs and direction of your business.

For this reason, it’s wise to consult with experts who can assess your process end-to-end, and advise you on how automation can uniquely serve your business. Click here to contact Aurora today, and learn more about what our industrial process solutions can do for you.